Custom plastic injection mold.

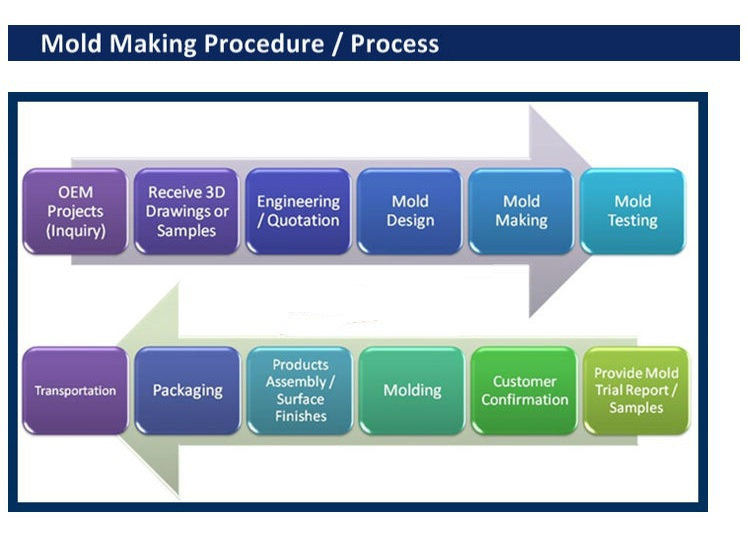

Product Specification:Custom plastic injection mold, designer and manufacturer of precision injection molds using engineering grade resins, glass, tungsten, carbon and iron filled materials for automotive, aerospace, electronics, marine, medical and telecom applications. Services include molding, overmolding, insert molding, in-house tooling, computer-aided design and manufacturing, product development, prototypes and models, materials evaluation, inspection, testing, maintenance and mold flow analysis. Secondary operations include assembly, CNC machining, ultrasonic welding, milling, reaming, tapping, heat inserting, decorating, hot stamping and special packaging. ISO 9001 compliant/ITAR compliant/CAGE Code 4EQV3. Special mold/tooling repair/refurbish services.

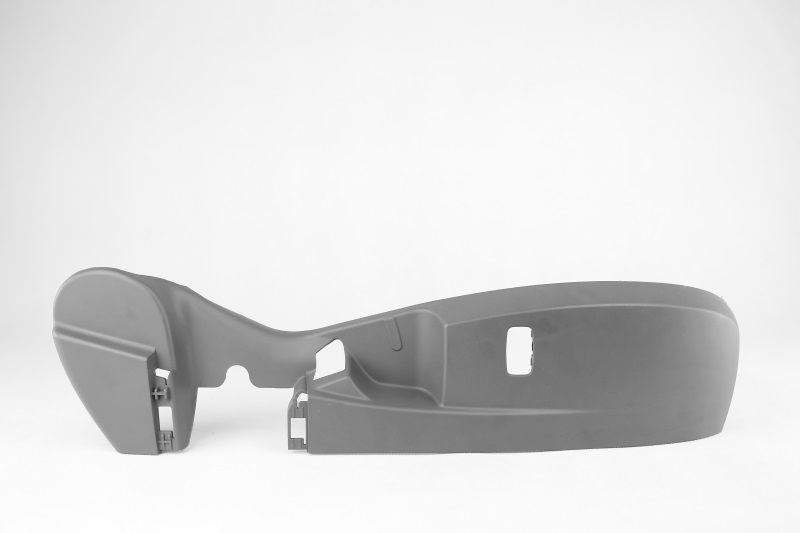

Jingmold is a expert of automotive plastic injection mold manufacturer, we specialize in automotive interior trim, automotive air condition, automotive car door trim and other automotive plastic components or parts.

General Mould For Reference

|

Items |

Description |

|

Mould Core |

DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13 etc. |

|

Hardness of steel |

46~56 HRC |

|

Molud Standard |

HASCO,DME,MEUSBURGER,JIS,CHINA LKM Standard |

|

Mould Base |

LKM&Hasco&DME standard (A,B plate 1730,2311,2312,P20 ) |

|

Cavity |

Single/Multi |

|

Runner |

Hot/Cold Runner |

|

Maximum Mould Size |

1500*1500 mm |

|

Surface of Mould |

EDM / High Polish&Texture |

|

Plastic material |

PP, PC, PS, PE, PET, POM, PA,PU, PVC, ABS,HIPS, PMMA etc. |

|

Mould Life |

300,000-1,000,000 shots |

|

Specification |

Depends on customer’s requirements. |

|

Surface Treatment |

Polish,texture,painting,screen printing,turnkey project |

|

Trade terms |

FOB Zhuhai,EXW ,CIF |

|

Export to |

Europe countries,USA,Mexico,Australia ,Middle-east ,Asia etc |

|

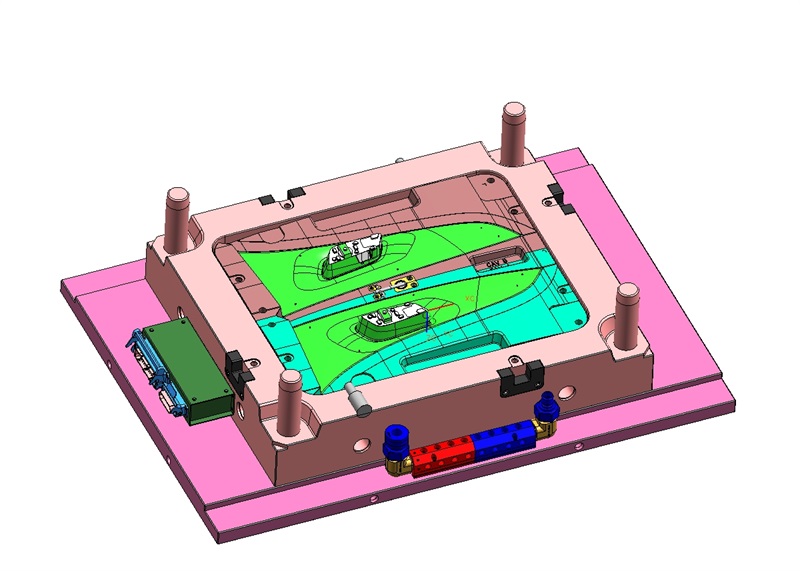

Mold hot runner |

DME, HASCO, YUDO,etc |

|

Mold cold runner |

point gate, side gate, subgate, tunnel gate,banana gate, direct gate ,etc. |

|

Mold hot treatment |

quencher, nitridation, tempering,etc. |

|

Surface finish of Part |

Logo print,Texture,Polishing,Painting,Chrome Plating |

|

Delivery time |

20-35 Days |

|

Outside package |

Standard wooden casesor as your requirement |

|

Inner package |

Stretch waterproof film & Each Mold painted ,anti-rust oil.3. Spare parts together with the mold shipment. |

|

Mold cooling system |

water cooling or Beryllium bronze cooling, etc. |

|

Items |

Description |

Please contact us now